This guide will help you find the right protective work gloves for you, or your workers.

Our guide will help you find the right protective work gloves. If you are still not sure which protective gloves to wear, contact our safety experts and we will help you find the right protection for you.

Always follow the instructions given and always wear protective gloves. If necessary, protect your hands also during your leisure time.

HOW TO CHOOSE THE RIGHT TYPE OF PROTECTIVE WORK GLOVES?

When choosing protective work gloves, it is good to check that they are of high quality and durable and therefore make your work smoother. Gloves should protect hands, be the right size and have the right properties and a good grip.

Gloves should be selected according to the task at hand and its risk assessment. Risk assessment must first

determine to which factors the workers' hands are exposed to at work and in the working environment, i.e. for mechanical, chemical, thermal (heat, cold) or biological factors. The assessment should also consider work risks and hazards, exposure, incl. the time of exposure, and frequency of risks/hazards at individual workplaces.

WHAT SIZE OF PROTECTIVE GLOVES SHOULD I USE?

Protective gloves should sit snuggly and be comfortable for the wearer, but also durable, strong and easy to put on. When choosing the right size of Jokasafe® protective work gloves, keep in mind that the glove should be smaller than you normally wear, because vinyl gloves have a looser fit. You may also wear either thin cotton or polyester gloves or warm teddy gloves or mittens inside your protective gloves to enhance the properties of protective gloves. You can see which size gloves to wear from the size chart below, see table 1.

Table 1. Sizing

|

Hand size |

Glove size |

|

XS |

6 |

|

S |

7 |

|

M |

8 |

|

L |

9 |

|

XL |

10 |

|

XXL |

11 |

WHAT DO THE MARKINGS ON THE PROTECTIVE GLOVES MEAN?

Protective work gloves are awarded the CE marking and the EN standard, if they meet the requirements specified in EU directive and standard. Protective work gloves must have a fixed marking, either on the glove itself, or on the package. Each manufacturer must have a declaration of conformity, which is an official document by which the manufacturer declares the product conforming to official requirements. Suppliers or sellers must produce the declaration of conformity upon request.

The permanent marking must include the CE marking, the name or logo of the manufacturer, the name or

product code of the glove, the size, the standard number, the pictograms, the levels or classes of protection, the date of production (type III).

CE-CLASSES

Protective work gloves are divided into three different risk categories based on risk severity.

- Class I - gloves protecting against low risks

- Class II - gloves protecting against other risks

- Class III gloves protecting against severe or life-threatening risks

EN STANDARDS

GLOVES PROTECTING AGAINST COLD

Protection level markings:

1. convection chill, protection level 0–4, best 4

2. contact cold, protection level 0-4, best 4

3. water permeability, protection level 0 (did not pass test) or 1 (passed test)

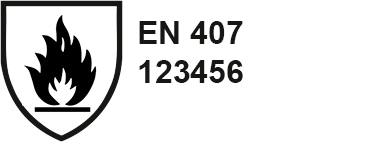

GLOVES PROTECTING AGAINST THERMAL RISKS (HEAT AND/OR FIRE)

Protection level markings:

1. fire properties

2. contact heat

3. flame contact

4. thermal radiation

5. small splashes of molten metal

6. molten metal splashes

GLOVES PROTECTING AGAINST MECHANICAL RISKS

Protection level markings:

1. abrasion resistance, protection levels 1-4, best 4

2. cut resistance (COUP-test), protection levels 1-5, best 5

3. tear resistance (Newton), protection levels 1-4, best 4

4. puncture resistance (Newton), protection levels 1-4, best 4

5. cut resistance (TDM-test), protection levels A-F, best F

6. impact resistance, fail/pass P (only marked, if passed the test)

X= feature not tested

0= protection level not meeting minimum requirement

The primary test method for cut resistance is the COUP test. The secondary test method is TDM-test, if COUPtest shows dulling of the blade, or manufacture needs to test the feature.

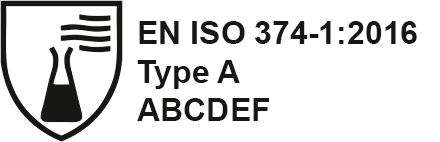

GLOVES PROTECTING AGAINST DANGEROUS CHEMICALS AND MICRO-ORGANISMS

Chemical protection labels:

Gloves protecting against chemicals fall into three different types.

Type A – protects against six test chemicals for at least 30 min (protection level 2)

Type B – protects against three test chemicals for at least 30 min (protection level 2)

Type C – protects against one test chemical for at least 10 min (protection level 1)

The third line on Type A and Type B pictograms indicates chemicals the glove will protect against, see table

2 below. Type C pictogram does not have a third line.

Table 2. Table of Chemical Tests

|

Letter Code |

Chemical |

CAS number |

Category |

|

A |

methanol |

67-56-1 |

alcohol |

|

B |

acetone |

67-64-1 |

ketones |

|

C |

acetonitrile |

75-05-8 |

nitrile mixture |

|

D |

dichloromethane |

75-09-2 |

chlorinated paraffin |

|

E |

carbon sulphide |

75-15-0 |

sulphur-containing organic mixture |

|

F |

toluene |

108-88-3 |

aromatic hydrocarbon |

|

G |

diethylamide |

109-89-7 |

amine |

|

H |

tetrahydrofuran |

109-99-9 |

heterocyclic ether mixture |

|

I |

ethyl acetate |

141-78-6 |

ester |

|

J |

n-heptane |

142-85-5 |

saturated hydrocarbon |

|

K |

sodium hydroxide 40% 40% |

1310-73-2 |

inorganic base |

|

L |

sulfuric acid 96% 96% |

7664-93-9 |

inorganic mineral acid |

|

M |

nitric acid 65% 65% |

7697-37-2 |

mineral acid |

|

N |

acetic acid 99% 99% |

64-19-7 |

carboxylic acid |

|

O |

ammonium hydroxide 25% |

7664-41-7 |

inorganic gas |

|

P |

hydrogen peroxide 30% 30% |

7722-84-1 |

general chemical reagent |

|

S |

hydrofluoric acid 40% 40% |

7664-39-3 |

inorganic acid |

|

T |

formaldehyde 37% |

50-00-0 |

organic gas, aldehyde |

Chemical gloves are tested for tightness, penetration, permeability, and mechanical resistance. The leak test tests the leakage of chemicals and / or microorganisms through the glove material. The permeability test tests the ability of the test chemical to penetrate through glove material. Based on the breakthrough time, a protection class is assigned to the protective glove, see table 3.

Table 3. Protection levels according to chemical breakthrough time

|

Time |

Protection class |

|

>10 min |

class 1 |

|

>30 min |

class 2 |

|

>60 min |

class 3 |

|

>120 min |

class 4 |

|

>240 min |

class 5 |

|

>480 min |

class 6 |

Always choose appropriate protective gloves when handling chemicals. The table below lists chemical groups

that the materials used in chemical gloves can resist, see table 4.

Table 4. Resistance of protective work glove materials by groups of chemicals

|

Group of chemicals |

Natural rubber |

Nitrile |

Neoprene |

PVC |

PVA |

Butyl |

|

Solvents |

x |

x |

|

|

|

|

|

Ketones |

x |

|

x |

|

x |

x |

|

Acids |

x |

x |

x |

x |

|

|

|

Hydrocarbons |

|

x |

x |

|

x |

|

|

Oils |

|

x |

x |

x |

x |

|

|

Fats |

|

x |

x |

x |

|

|

|

Organic solvents |

|

x |

x |

|

x |

|

Table 5. Chemical testing of gloves and mittens

|

Gloves and mittens with granulated surface EN ISO 374-1:2016 JokaHold, JokaHold Strong, JokaPolar, JokaTherm, |

Gloves and mittens with smooth surface EN ISO 374-1:2016 JokaArctic, JokaNordic, JokaOiler, JokaOiler Strong, |

||||

|

Applications of the tested chemicals |

CAS N:o |

Penetration level |

Min. breaktrough time (min) |

Penetration level |

Min. breaktrough time (min) |

|

K : Sodium hydroxide 40%, NaOH |

1310-73-2 |

6 |

480 |

6 |

480 |

|

L : Sulfuric acid 96%, H2SO4 |

7664-93-9 |

2 |

30 |

3 |

60 |

|

M : TNitric acid 65%, HNO3 |

7697-37-2 |

3 |

60 |

3 |

60 |

|

P : Hydrogen peroxide 30%, H2O2 |

7722-84-1 |

6 |

480 |

6 |

480 |

|

S : Hydrofluoric acid 40%, HF |

7664-39-3 |

6 |

480 |

5 |

240 |

|

T : Formaldehyde 37%, CH2O |

50-00-0 |

6 |

480 |

6 |

480 |

GLOVES PROTECTING AGAINST CHEMICALS AND MICRO-ORGANISMS

The standard measures the ability of a protective glove to protect users from microbes such as bacteria,

fungi, and viruses. Gloves must be tight according to the same tests as Chemical Protective Gloves.

GLOVES PROTECTING FROM ELECTROSTATIC DISCHARGES

Protective gloves that guide static electricity minimize the risk of explosion, and when worn, special footwear

must also be worn. Gloves alone do not provide total protection.

PROTECTIVE GLOVES FOR WELDERS

Type A – gloves are thicker and offer better protection than Type B gloves

Type B – gloves for jobs requiring finger dexterity, e.g., TIG-welding

SYMBOLS

APPROVED FOR FOODSTUFFS

TOUCH-SCREEN FEATURE

ESD-FEATURE